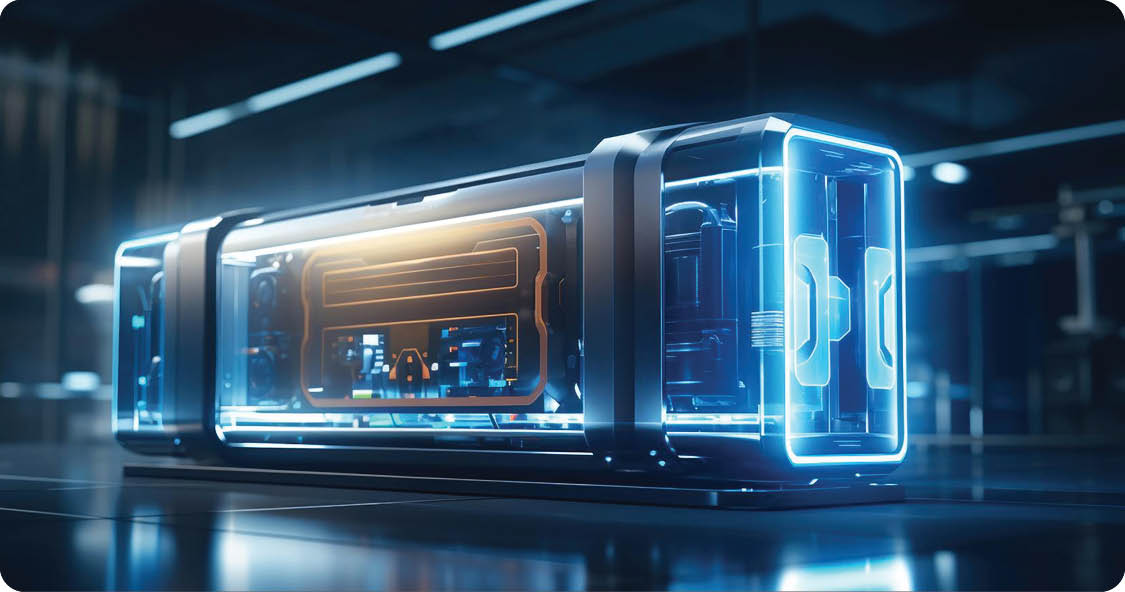

Solid-State Batteries for Next – Generation Electric Vehicles

Dr. Paul Sathiyan - Director, Automotive Power Electronic Drives, AIoT, MBS

The global Solid-State Batteries (SSB) market is projected to experience robust growth in the coming years, driven by increasing demand for Electric Vehicles (EV), consumer electronics, and energy storage systems. Market analysts forecast a compound annual growth rate (CAGR) exceeding 50% during the forecast period, indicating strong momentum for solid-state battery technology. SSB has emerged as a promising solution to address the limitations of conventional lithium-ion batteries, offering higher energy density, improved safety, and enhanced longevity on a single charge. Unlike traditional batteries that use liquid electrolytes, SSB utilize solid electrolytes such as ceramics or polymers, which eliminate the risk of electrolyte leakage and dendrite formation, leading to safer and more reliable energy storage solutions. Moreover, SSB exhibit superior thermal stability compared to their liquid electrolyte counterparts, reducing the risk of thermal runaway and enhancing overall battery safety. This inherent safety feature is particularly crucial for EVs, where battery fires pose significant concerns for vehicle occupants and first responders.

In addition to improved safety and energy density, SSB offer the potential for extended cycle life, reducing the need for frequent battery replacements and lowering the total cost of ownership for EV owners. By employing stable electrolyte materials and advanced electrode designs, SSB can withstand thousands of charge-discharge cycles without significant degradation, enhancing the durability and reliability of EV powertrains. Several companies and research institutions are at the forefront of solid-state battery development, including Toyota, BMW, QuantumScape, and Solid Power.

However, despite their promising attributes, SSBs face several challenges that must be overcome before they can be widely adopted in commercial EVs. These challenges include cost reduction, manufacturing scalability, ensuring adequate performance under real-world operating conditions, selection of materials and meeting safety standards.

1. Cost: The manufacturing cost of SSB remains high due to the complexity of production processes and the use of specialized materials. Achieving cost parity with conventional lithium-ion batteries is essential for mass adoption in the automotive sector.

2. Scalability: Scaling up production to meet the demands of the automotive industry is a significant challenge. Developing scalable manufacturing processes that ensure consistency, reliability, and cost-effectiveness is critical for commercial success.

3. Performance Under Real-World Conditions: SSB must demonstrate performance and durability under diverse operating conditions, including temperature extremes, rapid charging, and high cycle counts. Ensuring reliability and longevity is essential for gaining consumer trust and acceptance.

4. Material Challenges: Finding suitable solid electrolyte materials that exhibit high conductivity, stability, and compatibility with electrode materials is crucial. Additionally, optimizing electrode-electrolyte interfaces to minimize resistance and maximize energy density remains a focus of research.

5. Safety Certification: Meeting stringent safety standards and obtaining certification for automotive applications is a prerequisite for commercialization. Ensuring that SSB can withstand mechanical stress, thermal fluctuations, and other adverse conditions is paramount for regulatory approval.

Research and development endeavors are currently in progress to tackle these obstacles and hasten the integration of SSB into automotive applications. Collaborative efforts among industry stakeholders, research institutions, and government agencies are essential to foster innovation, expedite technological advancements, and establish resilient supply chains. While initial prototypes have demonstrated encouraging outcomes concerning energy density and safety, the challenge of ramping up production to meet the demands of the automotive industry persists. Despite the challenges, the potential advantages of solid-state batteries, encompassing superior energy density, safety, and longevity, position them as a compelling option to drive the evolution of electric vehicles and energy storage systems into the future.