Artificial Intelligence in ASD

EinNext Biosciences

Autism Spectrum Disorders (ASD) comprise a group of neurodevelopmental abnormalities that begin in early childhood characterized by difficulty with social communication and interaction, restricted interests, and repetitive behaviors. According to the latest international data, the incidence of ASD has increased from 150:1 in 2000 to 36:1 in 2017, making it the leading cause of disability in children. With estimates of 2% of the children diagnosed with ASD in the US, researchers should investigate treatment methods, intensity, duration, and outcomes.

The Challenge:

Although the exact cause of ASD remains unclear, current studies suggests that it may be associated with genetic factors, abnormal brain structure and environmental factors. Since autism spectrum disorder varies widely in symptoms and severity, with no specific medical test to diagnose the disorder, diagnosing ASD can be difficult. Healthcare providers diagnose the condition based on standardized assessments of the patient’s history and behavior. Although ASD can be diagnosed as early as 15- 18 months of age, many children do not receive a final diagnosis until they are in their adolescence or adulthood.

Early diagnosis and intervention are imperative for timely effective treatments to minimize symptoms, and to improve long-term outcomes related to cognition, language, adaptive behavior, daily living skills, and social behavior for children with ASD. Additionally, accurate identification is challenging as ASD is often enmeshed with other neurodevelopmental disorders, and medical comorbidities.

AI in Autism Research:

Since existing solutions for diagnosis of ASD are both resource-intensive and cost-intensive, Artificial intelligence (AI) is a potential solution to this issue. Autism spectrum disorder research has yet to leverage big data on the same scale as other fields. Advancements in easy, affordable data collection and analysis may soon make this a reality.

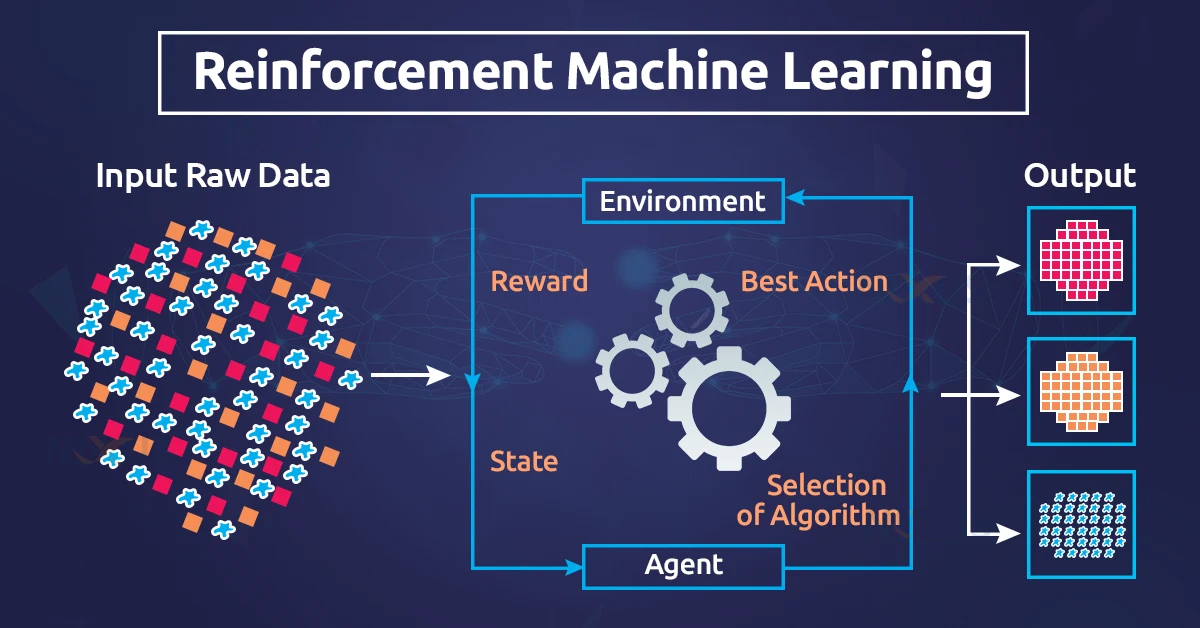

The high prevalence rate and heterogeneous nature of ASD have led some researchers to turn to machine learning over traditional statistical methods for data analysis. In the last decade, study of AI in Autism has shown a remarkable increase in trend. The availability of various machine learning toolkits, such as Hadoop, TensorFlow, Spark, and R, has led to unique opportunities for researchers to leverage machine learning algorithms.

The high prevalence rate and heterogeneous nature of ASD have led some researchers to turn to machine learning over traditional statistical methods for data analysis. In the last decade, study of AI in Autism has shown a remarkable increase in trend. The availability of various machine learning toolkits, such as Hadoop, TensorFlow, Spark, and R, has led to unique opportunities for researchers to leverage machine learning algorithms.

Hotspots and Research Fronts:

To improve screening and diagnosis, Machine learning algorithms—such as SVMs— have been used in ASD research. These models have been shown to improve the accuracy of diagnoses and provide insight into how different characteristics (such as standardized assessments, eye movement data, upper limb and general kinesthetic data, and neuroimaging data) can aid in the differential diagnosis of ASD. Standardized assessments that are currently in use have a potential for misdiagnoses, particularly when distinguishing one disorder from another. Machine learning procedures can discriminate individuals with ASD from individuals with attention deficit hyperactivity disorder (ADHD) with a high level of accuracy.

Machine learning has also been implemented in examining neuroimaging data. The symptom severity of individuals with ASD based on cortical thickness using support vector regression (SVR) and ENet penalized linear regression has been studied. Machine learning models, including RF, to analyze neuroimaging data for diagnostic classification purposes have also been implemented.

Longitudinal data captured at multiple points in development (8 and 14 months of age) for high-risk siblings has been used to increase accuracy of predicting ASD diagnosis at 36 months. Deep learning has been used to study predictors of challenging behavior and analyze neuroimaging in individuals with ASD.

While data from the electronic health records of decedents with an ASD were used to build a random forest classifier to examine the life-time health problems of those with ASD, the impact of parental age on the risk of developing ASD has been evaluated using logistic regression.

Machine learning has also been applied in ASD genetics research, allowing researchers to determine which genes are related to ASD. These findings highlight the potential of machine learning to improve understanding of the role genes play in the development of ASD.

Based on this approach, we are currently developing a cloud-based platform called EinNel MDOX that connects engineers, data, and resources to effectively model and optimize vehicle designs using real-time data from simulations, physical tests, and field tests. By harnessing the full potential of the cloud, organizations no longer need to rely on high-end computing hardware and validate complex designs with less computing power, allowing engineers to work from anywhere and anytime.

Based on this approach, we are currently developing a cloud-based platform called EinNel MDOX that connects engineers, data, and resources to effectively model and optimize vehicle designs using real-time data from simulations, physical tests, and field tests. By harnessing the full potential of the cloud, organizations no longer need to rely on high-end computing hardware and validate complex designs with less computing power, allowing engineers to work from anywhere and anytime.

EinNel drives the automotive and manufacturing industries toward streamlining their product development process through the use of platform engineering. By centralizing their distributed functions under a single platform, EinNel enables these industries to reduce the number of iterations required and improve data management. This allows for quick and easy access to data, which can greatly accelerate product development.

EinNel drives the automotive and manufacturing industries toward streamlining their product development process through the use of platform engineering. By centralizing their distributed functions under a single platform, EinNel enables these industries to reduce the number of iterations required and improve data management. This allows for quick and easy access to data, which can greatly accelerate product development.